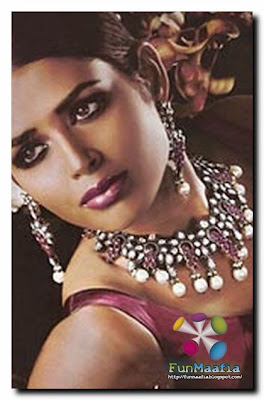

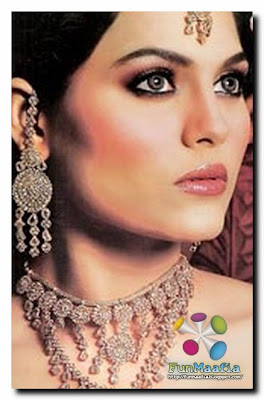

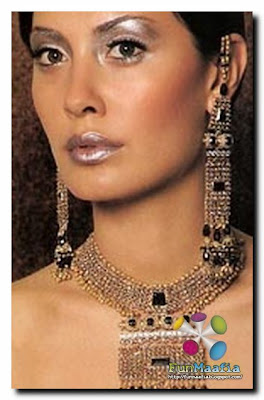

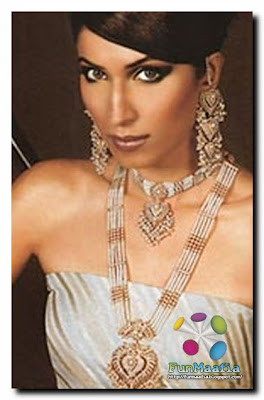

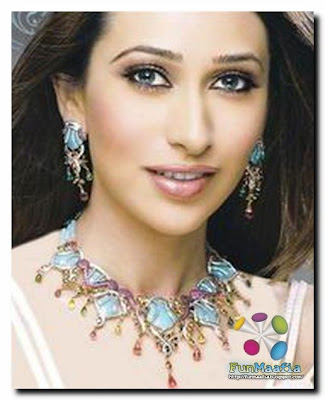

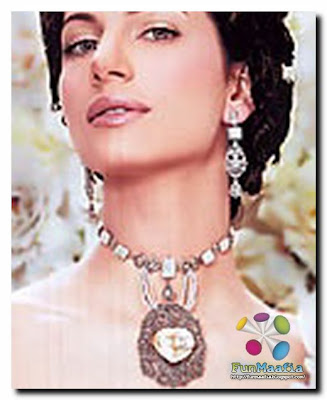

Here are a few bridal party jewelry designs from Pakistan and India. Hope you like this bridal jewelry just as you have loved out previous articles on Jewelery and Mehndi.

Wednesday, March 31, 2010

Outlier: A Brand at work...

Outlier offer tailored performance clothing for cycling in the city.

Outlier offer tailored performance clothing for cycling in the city.Outlier is a Brooklyn based clothing company owned by Abe Burmeister and Tyler Clemens who offer tailored perfomance clothing for cycling in the city. Despite rarely cycling myself (London's roads are far too frightening for that) I have kept a close eye on the development of the label. I first heard about them over on Gentleman's Corner, where the ever reliable ear to the sartorial ground that is Jason Dike acquainted me with their range of future classics. Since the brand produced their first garment, trousers in 2008, Outlier have carved out an interesting niche in two saturated and blogging favourite markets, fashion and cycling. When they started out neither of the duo really knew how to make clothing. They just knew that they couldn't find the garments that that wanted and if no one else was going make them then we would have to do it ourselves. They began hunting down the best technical fabrics in the world and brought them to small factories in New York City where craftsmanship still reigns supreme. Through a constant process of experimentation and refinement they started producing a line of goods that they were proud of. Their company tag line of 'tailored performance,' refers to their primary inspiration and motivation as urban bike commuters. From the first pair of trousers, they’ve worked slowly but surely to expand a line of clothes they consider future classics and who can disagree. Incrementally adding to their catalogue rather than reinventing itself each season like traditional fashion companies. They design one item at a time, and every time they release a new run of an item they try to improve it. Sometimes they start with a problem that needs solving. Sometimes they start from studying form and motion and trying to make a better cut garment. The more I hear about this brand this brand I am inspired. Following my recent post on Postalco, Michael from Tramnesia dropped me an email to thank me for the mention and to nudge me in the direction of his latest series of videos which just so happen to be on Outlier...

The video posted above is a short trailer for a much longer feature that documents the development and production of a single garment, a shirt. As part of their Working series, the inquisitive folks at Tramnesia were drawn to Outlier’s story because it underscores so many of the challenges involved in running a small business, especially in New York City. As they produce locally, Tramnesia were particularly curious to see how their production process worked when so much of New York’s once mighty garment industry has been offshored and lost. Visiting the garment district today is a clear reminder of that past; it still remains a hive of small-business activity, albeit smaller and less visible. Their visits to Outlier over the course of six months to the garment district showed us a network of small businesses, a microcosm of the city at large with its layers of inter dependencies. As they will readily acknowledge, Outlier is a business born of and reliant on New York’s resources. Outlier proves how despite knowing little about clothing, good ideas and resourcefulness can go a long way in establishing a business. The full-length, ten part feature learns about Outlier by observing the company at work. The first two parts are available to watch online and a third one is imminent. So why not make yourself a cup of tea, head over to Tramnesia and watch a brand at work....

Tuesday, March 30, 2010

Dr Martens: Fifty years old and still going strong

For five decades Dr Martens famous 1460 boot has been worn by the ordinary workers for whom it was designed but also by rebels and non-conformists of all stripes. It was adopted first by the skinheads, later by other sub-cultures and was often worn by musicians for its authentic, working-class appeal. The brand and music have been closely associated for fifty years so to celebrate their anniversary Dr Martens has enlisted ten contemporary bands and ten film directors to help celebrate the landmark. The result is a collection of music and videos that reflects the broad range of groups who have adopted and customised Dr Martens over the last 50 years. All of the videos will be available to view on the brand's site as of the 1st April 2010 but for now, I just want to concentrate on the product. As promised in yesterday's factory porn post I can now share information of the latest product releases. To celebrate their 50th Anniversary Dr Martens are launching a commemorative limited edition footwear collection and I was afforded a sneak preview during my trip to their Wollaston factory.

Celebrating fifty golden years of Dr Martens. The limited edition iconic eight eye 1460 boot and the classic three eye 1461 shoe.

Celebrating fifty golden years of Dr Martens. The limited edition iconic eight eye 1460 boot and the classic three eye 1461 shoe.The commemorative and limited collection consists of two styles, the iconic eight eye 1460 boot and the classic three eye 1461 shoe, both of which are presented in Black and Cherry Red colours – those synonymous with the brand. The leather used is a rich premium Polished Pebble that will feature exclusively on this range. Each style will be restricted to limited runs of 1,460 pairs per colour for the boots and 1,461 pairs per colour for the shoes globally. However, despite being extremely limited and handcrafted at their Wallaston factory in Northampton the price points are pretty darn accessible at at £110 for the 1460 and £100 for 1461.

Despite it being their birthday, Dr Martens are going to be extremely busy on the 1st April, as the date also sees the launch of their Worn 1460 collection. The iconic boot is treated with an eight step 'Worn' process to give its wearer a head start to the breaking in ritual. The boots retain the features of the original 8-eye style but have the appearance of being lived in and loved for years. The Worn 1460 boots are made in a faithful way to the specifications of Dr Martens originals but are subsequently rolled, creased, flexed, brushed, distressed, polished, sand-blasted and roughed up to create aged classics with an authentic feel. Personally, I love nothing more than breaking in a pair of new boots (that's the real fun part, right?) but for the lazy amongst you this treatment should be of interest and I can testify that the result is quite beautiful.

Now, I have been prattling on about the iconic styles for some time now but there is so much more to this brand than the classics we all know and love. I felt like a fat kid in a sweet shop as I discovered new styles and I'm excited to share them with you. For some of the models (see immediately above and below) I don't have too much information to share with you aside from the fact that I like them! The coloured sole products (above and below) are an evolution from a collection they did previously called Primary where they are all red, all blue. This range is called 'Modern Classics' and I love the bold colourways used. These will certainly get your feet noticed.

Now, I have been prattling on about the iconic styles for some time now but there is so much more to this brand than the classics we all know and love. I felt like a fat kid in a sweet shop as I discovered new styles and I'm excited to share them with you. For some of the models (see immediately above and below) I don't have too much information to share with you aside from the fact that I like them! The coloured sole products (above and below) are an evolution from a collection they did previously called Primary where they are all red, all blue. This range is called 'Modern Classics' and I love the bold colourways used. These will certainly get your feet noticed.

In recent years, Dr Martens have been making a proactive effort to expand their brand offering. Since taking over at the creative helm, Andrew Bunney and the lovely Tommy have really helped the brand move forward, with new make ups and styles and arguably most importantly through a number of high profile collaborations. Through collaboration with a number of well selected bands including the likes of Raf Simons, Jean Paul Gaultier, Uniform Experiment and numerous art based projects the brand offering has evolved in to new styles and collections. The below range seems a natural progression from the recent collaborative work with street wear legends Stussy.

The Prism collection has supple suede uppers with tonal stitch and welt colours. Based on Dr Martens' classic 3-eye shoe, Chukka and Monkey boot, this collection has a fresh feel to it. The range uses three materials, suede, leather (smooth, medium sheen) & leather (high-polish). The desert boot is Manton, the monkey boot is Philip.

The Prism collection has supple suede uppers with tonal stitch and welt colours. Based on Dr Martens' classic 3-eye shoe, Chukka and Monkey boot, this collection has a fresh feel to it. The range uses three materials, suede, leather (smooth, medium sheen) & leather (high-polish). The desert boot is Manton, the monkey boot is Philip.

As well as making obvious strides forward it is great to see the brand keeping its core values. The Vintage collection sums this point best. The collection is handcrafted in the original Wollaston factory, by cobblers using the original construction techniques that were developed in the 1960's.

The product, made on the original '59' last, features narrower horizontal tread bars, criss-crossed coring bars, a darker sole, a storm welt bound together on the lateral side, small indentations left on the welt by the original stitching machine, no top collar binding and runs into the eye stay above the top eyelet. This is where it all began and it is refreshing to see it still going strong after all of these years. For AW10, Dr Martens adds a certain amount of bold colour and design to its 'Made in England' arm. These are Dr Martens but not as we know them. I hope this post demonstrates one of the key feelings I was left with after my tour of their Wollaston base. In short it is this... that despite turning fifty and the fact that it is deservedly proud of its past, this is a brand that is keen to move forward and I, for one, look forward to its future.

Any given Sunday...

Is there anything better than waking up late on a Sunday morning to the aromas of a cooked breakfast and a cafetiere of quality coffee and the sights of a bright Spring morning and a crisp copy of your favourite weekend newspaper? This scenario can only be bettered by the fact that the aforementioned Sunday publication includes a copy of O, the Observer's Fashion Supplement by Tank dedicated to fashion four times a year...oh and replace Sunday with Tuesday! Ha! Issue nineteen of the well read supplement is dedicated to menswear and Spring/Summer '10. The astute amongst you will know that it came out two Sunday's ago but I'm playing catch up because I was out of the country and well, this magazine is just too good to miss. In this issue we learn that Renzo Rosso, founder of Diesel wants to build a luxury empire without the luxury bit, are reminded how one of the UK's most radical designers, Aitor Throup has ended up making the kit Englan will wear in this summer's world cup as well as listening in to a conversation with menswear designer and photographer Tamburlain Gorst. So, humour me...pour yourself a coffee, close your eyes and pretend that it is Sunday...

The stars of the season reveal their picks for the season.

In addition to offering their own essentials for the warmer months ahead including espadrilles by Paul Smith, a canvas suitcase from Pickett and aviator sunglasses from Fabris Lane, the O team ask a few of the stars of the season for their own personal picks. On such star is Marc Hare who offers his tips for hot legs this summer. Mr Hare's four picks include Mr Hare Capotes, Turnbell & Asser socks, James Long leather biker trousers and Opi nail varnish in jade. For the latter he concedes that after wearing elegant shoes every day, the aesthetic of his bare feet just wasn't cutting it so now you can tell he is Mr Hare even without the shoes. One thing is for certain, I'll be looking down at his feet next time I bump in to him.

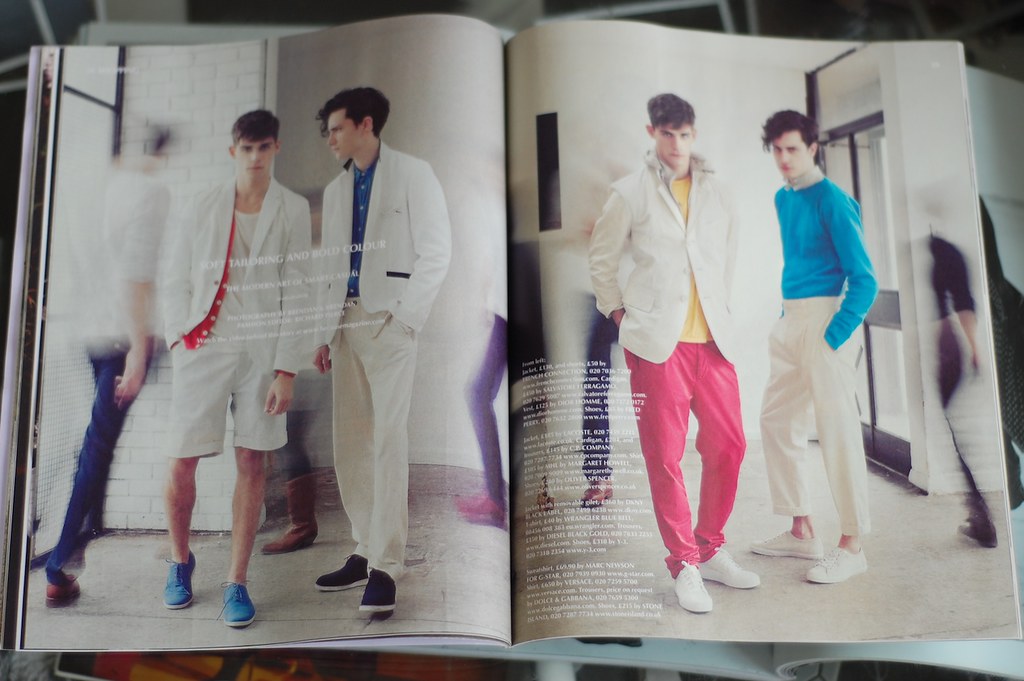

Soft Tailoring and Bold Colour. Photography by Brendan & Brendan with Richard Pierce as Fashion Editor

The supplements contains one of the strongest editorials I have encountered so far this season. Soft Tailoring and Bold Colour does exactly what it says on the tin by dishing up the modern art of smart casual. The stills see in the magazine are actually screen grabs taken from a video which is available to view over on Because Magazine. During this video models Broed and Tristan suffered for their art by holding their poses while gallery visitors milled around in the background. For me, both the stills and video feel like a fresh spring fashion breeze.

Soft Tailoring and Bold Colour. Photography by Brendan & Brendan with Richard Pierce as Fashion Editor

One of the key fashion articles within these pages is penned by editor Peter Lyle who discusses how after a decade of seemingly mutual suspicion, high fashion and sportswear has finally got something interesting to talk about again and how he sees the new England kit as just the beginning of a rekindled relationship.

Sport and Fashion. The example of Aitor Throup

The way in which sport's influences on men's fashion surges and shrinks has always been fascinating to me and I'd love to look at the issue with a bit more historical insight one day (just add that to the list of blog topics I've been promising) but Aitor Throup certainly represents and interesting development. My thoughts on the designer are well discussed throughout this blog but it is always a pleasure to be reminded that one of the UK's most exciting design talents has ended up designing the kit that England will wear in this summer's World Cup.

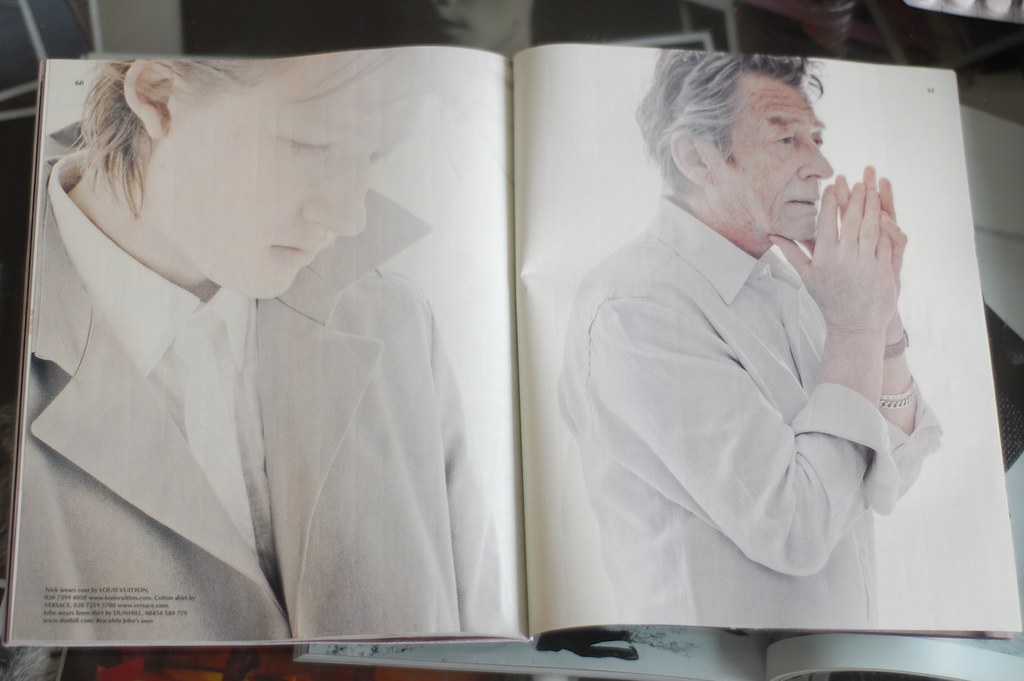

The Son Also rises, Nick and John Hurt.

If my eyes were not dazzled enough by the featherlight tailoring and bold colour of the previous editorial they are then introduced with the sight of John and Nick Hurt wearing the very best of this season's heritage and workwear inspired pieces. The duo certainly dress and play the part well. The acting legend and his rising son bring a sense of real integrity and substance to the clothes.

There is something dirty about lazily flicking through these pages intended for weekend eyes on a dull Tuesday but I like it. Why can't every day be Sunday and why can't every Sunday offer something as thoughtful and as varied as O?

Monday, March 29, 2010

Dr Martens: The craft of an iconic shoe

On April 1, 1960 the first pair of Dr. Martens was produced by the Griggs factory in the village of Wollaston in central England. Eight eyelets, ox blood red with distinctive yellow stitching, the design was dubbed "1460" after the date of its creation. More than one hundred million pairs of Dr. Martens have been sold since that first pair was unveiled 50 years ago, although there are now some two hundred and fifty different models, from golden to fuscia, floral to custom patterned. To help celebrate reaching landmark Dr. Martens invited a few of us bloggers (including the lovely Disney Roller Girl, Dapper Kid, The Clothes Whisperer) up to their Wollaston factory to help cover the event. Over the next few days I will look at the brand's anniversary campaign and share my favourite models for AW10 but for the benefit of brightening up your Monday evening, I want to offer you a little shoe and factory porn...

Happy Birthday to you... Dr. Martens is fifty on 1st April.

Happy Birthday to you... Dr. Martens is fifty on 1st April.In a sign of the times, the majority of Dr. Martens models have been made in Asia since 2002. However, around fifty pairs leave the factory in Wollaston every day, including the vintage 1460 model, made by ten or so workers on old machines. The Vintage collection is handcrafted in the by cobblers using the original construction techniques that were developed in the 1960's. Today, I was fortunate enough to watch the craftsmen at the Wollaston factory work, following each well honed and practiced process from start to finish. Brian, a lovely and knowledgeable chap who has been working at the factory for thirty seven years talked us through each stage. He professed that his favourite Dr. Martens model is the classic oxblood 1460 and confessed that he used to use black polish to stain the leather. I just wish that I had recorded everything he said so that I could create an awesome mix for you but I'm afraid that I'm not that organised or skilled...you will just have to make do with my factory shots...

The first stage, moulding. The injection moulding of the sole sees the rubber pellets heated up to 170 degrees celsius as they fill the two part cavity. They are left for twenty four hours cool.

The first stage, moulding. The injection moulding of the sole sees the rubber pellets heated up to 170 degrees celsius as they fill the two part cavity. They are left for twenty four hours cool.

Brian talked us through the different aspects of the hide and the fact that the skill of the craftsmen ensures that the best of the leather is used for the uppers (as a rule, the further back you go on the animal, the better the quality of skin) and that there is minimal wastage. I was surprised at how much of this was done by hand.

Brian talked us through the different aspects of the hide and the fact that the skill of the craftsmen ensures that the best of the leather is used for the uppers (as a rule, the further back you go on the animal, the better the quality of skin) and that there is minimal wastage. I was surprised at how much of this was done by hand.

We were then introduced to Carol who helped transform the hide in to a more recognisable show form...

We were then introduced to Carol who helped transform the hide in to a more recognisable show form...

It was great to watch the craftsmen at work, most of which have been working at the factory for many years. I just had to take a sneaky shot of Carol's copy of Good Housekeeping.

It was great to watch the craftsmen at work, most of which have been working at the factory for many years. I just had to take a sneaky shot of Carol's copy of Good Housekeeping.

Three row stitching. This machine was pretty frightening and worked shockingly fast. They then moved on to the eyelet punching machine.

Three row stitching. This machine was pretty frightening and worked shockingly fast. They then moved on to the eyelet punching machine.

Throughout the show making process the leather loses moisture so here the uppers are placed in a steam machine to soften the leather.

Throughout the show making process the leather loses moisture so here the uppers are placed in a steam machine to soften the leather.

The shoe is readied for the welted sole...Every single pair of Dr. Martens has exactly 49 stitches around the sole, regardless of shoe size

The shoe is readied for the welted sole...Every single pair of Dr. Martens has exactly 49 stitches around the sole, regardless of shoe size

This piece of kit took my breath away as the sole was fixed to the shoe. The iconic Air Soles are literally melted on to the welt.

This piece of kit took my breath away as the sole was fixed to the shoe. The iconic Air Soles are literally melted on to the welt.

The finished shoe. A recognisable icon, the vintage Cappers.

The finished shoe. A recognisable icon, the vintage Cappers.

The first stage, moulding. The injection moulding of the sole sees the rubber pellets heated up to 170 degrees celsius as they fill the two part cavity. They are left for twenty four hours cool.

The first stage, moulding. The injection moulding of the sole sees the rubber pellets heated up to 170 degrees celsius as they fill the two part cavity. They are left for twenty four hours cool. Brian talked us through the different aspects of the hide and the fact that the skill of the craftsmen ensures that the best of the leather is used for the uppers (as a rule, the further back you go on the animal, the better the quality of skin) and that there is minimal wastage. I was surprised at how much of this was done by hand.

Brian talked us through the different aspects of the hide and the fact that the skill of the craftsmen ensures that the best of the leather is used for the uppers (as a rule, the further back you go on the animal, the better the quality of skin) and that there is minimal wastage. I was surprised at how much of this was done by hand. We were then introduced to Carol who helped transform the hide in to a more recognisable show form...

We were then introduced to Carol who helped transform the hide in to a more recognisable show form... It was great to watch the craftsmen at work, most of which have been working at the factory for many years. I just had to take a sneaky shot of Carol's copy of Good Housekeeping.

It was great to watch the craftsmen at work, most of which have been working at the factory for many years. I just had to take a sneaky shot of Carol's copy of Good Housekeeping. Three row stitching. This machine was pretty frightening and worked shockingly fast. They then moved on to the eyelet punching machine.

Three row stitching. This machine was pretty frightening and worked shockingly fast. They then moved on to the eyelet punching machine. Throughout the show making process the leather loses moisture so here the uppers are placed in a steam machine to soften the leather.

Throughout the show making process the leather loses moisture so here the uppers are placed in a steam machine to soften the leather. The shoe is readied for the welted sole...Every single pair of Dr. Martens has exactly 49 stitches around the sole, regardless of shoe size

The shoe is readied for the welted sole...Every single pair of Dr. Martens has exactly 49 stitches around the sole, regardless of shoe size This piece of kit took my breath away as the sole was fixed to the shoe. The iconic Air Soles are literally melted on to the welt.

This piece of kit took my breath away as the sole was fixed to the shoe. The iconic Air Soles are literally melted on to the welt. The finished shoe. A recognisable icon, the vintage Cappers.

The finished shoe. A recognisable icon, the vintage Cappers.I was amazed at how quickly the hide was transformed in to the iconic model we see above. The product, made on the original '59' last, features narrower horizontal tread bars, criss-crossed coring bars, a darker sole, a storm welt bound together on the lateral side, small indentations left on the welt by the original stitching machine, no top collar binding and runs into the eye stay above the top eyelet. This is where it all began and it is great to be reminded of that.

Subscribe to:

Posts (Atom)

Popular Posts

-

As you should all know by now, Close Up and Private is an on going project by artist Sergei Sviatchenko which looks to capture the spirit o...

-

Also our old blogger friend STUART SEMPLE asked us to let you know they are running evening events in conjunction with the exhibition at T...

-

A good designer is like an attentive waiter: he is there to serve his guests and quietly depart. Fashion, as Cristobal Balenciaga famously a...